Hatching egg quality is a crucial parameter to maximise the number of day-old chicks per hen and thus the profitability of the breeder flock. As such, starting from oviposition at the farm, special care has to be given to the hatching eggs to preserve their hatchability potential.

The aim is to protect embryo liveability, which leads to improved hatchability and chick quality. The eggs must not be incubated before the breeder flock reaches 24 weeks of age, using a minimum egg weight of 50-52g.

The egg at oviposition contains an embryo of 30,000-60,000 cells, and must be preserved to achieve good hatchability and chick quality. With optimum care the fertile egg will produce a healthy chick; conversely, with improper care both hatchability and chick quality will be greatly affected.

Egg handling

Maintaining the embryo’s viability is the main priority from oviposition to hatchery storage. Eggs need to be stored at ‘physiological zero’, a temperature below which there is no embryonic development. This temperature has been reported at different levels in literature, varying from 14-28°C.

The main risk to the embryo comes from bacterial contamination immediately after the egg has been laid. As it cools down, the egg content retracts and air enters through pores in the eggshell. If the environment (litter, nest floor) is dirty, bacteria will invade the shell and be difficult to kill. Dirty nests and floor eggs are often the main reason for exploding eggs in the setters, and for chick contamination by Pseudomonas and Aspergillus. Nests must be kept clean at all times. Nests should be equipped with a closing or ejection system to avoid nest occupation and soiling at night.

Embryo development will stop when the internal egg temperature reaches 20˚C (also referred to as physiological zero). Depending on ambient temperatures, the temperature in the nests may reach 30˚C as a result of the hens’ body heat and the litter acting as an insulating material. If eggs are left for too long in these conditions, the embryo starts to develop and becomes more sensitive to subsequent environmental change. This becomes more acute as the flock ages.

Several factors can affect the egg-cooling rate and must be given due consideration, such as egg collection frequency and nest type. In manual nests, eggs must be collected at least four times daily in temperate climates, and more often in cold or in hot climates. Picture shows a poor quality manual nest.

It is also important to consider the incidence of hairline cracks resulting from large numbers of eggs in the nest or overcrowding on the transportation belt. Egg collection is carried out using either new carton trays or previously disinfected plastic or setter trays. Uniform egg cooling can only be achieved with a minimum level of air circulating among the eggs.

| RULE OF THUMB TO MAINTAIN EGG QUALITY AFTER OVIPOSITION | → The egg is a living organism: handle it with care. → The integrity of the hatching egg must be preserved at all times, from the farm to the hatchery. → Ensure smooth handling to protect the eggshell and its contents. → Avoid hairline cracks by using adequate plastic egg trays. → Nest design must be adapted to reduce the incidence of cracked, broken eggs. → Nest hygiene must be impeccable at all times in order to avoid contamination. → In manual nests, collect eggs at least four times a day. → Maintain a steady temperature around the eggs in the collection room; around 20˚C on average (range 18-20˚C). → Ensure smooth cooling in setter or plastic tray with sufficient airflow. → Floor eggs must be managed in a specific way to avoid cross- contamination with nest eggs. → If floor eggs are loaded, collect and handle separately, and identify them; they must be loaded in a separate setter. → Keep in mind that cracking and breaking increases bacterial contamination and the risk of explosion. → Incorrect egg selection decreases chick quality and hatchability percentage |

Egg transportation from farm to hatchery

Breeder farms are often located away from the hatchery. Thus, transportation is an intermediary step between farm and hatchery storage. This requires that optimal conditions are applied during transportation to preserve the egg and embryo quality.

| RULE OF THUMB FOR OPTIMAL TRANSPORTATION CONDITIONS | → Use a dedicated vehicle for hatching egg transportation. → The vehicle and all transport equipment must be cleaned and disinfected prior to any egg transport. → Transport temperature should be as close as possible to that of the farm storage room: ♦Lower transport temperature: contraction of the eggs’ contents induces air penetration, which increases the risk of contamination ♦Higher transport temperature: risk of egg sweating as egg surface is colder than external temperature, which increases the risk of contamination. Be careful, as sweating can also occur during loading and unloading of the eggs. → During transportation, handle the eggs with care and avoid any bumps or jolts. It is recommended that you use vehicles with good suspension and only take roads which are in good condition. |

Egg disinfection

Disinfection of eggs whilst they are still warm is the best way to prevent bacterial or fungal penetration into the egg. Furthermore, disinfection of the egg shell surface has little effect on contaminants that have already penetrated the egg shell.

This underlines the importance of frequent egg collection (4-5 times daily) to take advantage of disinfection as the air cell is formed. Infrequent egg collection reduces disinfection efficiency. However, proper egg collection and disinfection techniques on their own do not guarantee clean quality eggs.

Shell quality plays a major role in preventing contamination, and it is essential to do everything possible to ensure that it is optimal.

Several studies have shown that the length of time that eggs are exposed to bacteria plays a less important role than the thickness of the shell in preventing contamination.

Methods of disinfection

Whichever method is chosen, disinfection should not be considered efficient unless the shell is clean. It is rare that disinfectants are effective against organic material or dust.

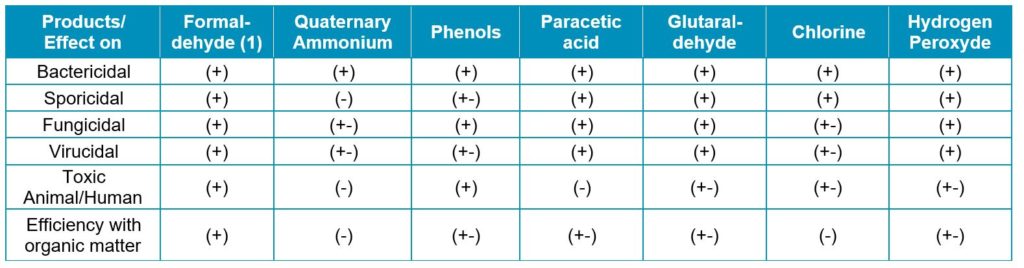

The two most efficient and widely used methods are fumigation and spraying. Other alternative methods can also be used. Table 1 shows some products available on the market to sanitise hatching eggs.

| RULE OF THUMB TO MAINTAIN EGG QUALITY AFTER DISINFECTION | → Disinfect the egg shell as soon as possible after oviposition. → Ensure optimal distribution of the product all around the eggs. → Be aware of the impact of high concentrations of Formalin, if used and allowed by local authorities. → The use of peroxide or glutaraldehyde or peracetic acid to sanitise eggs is common in many hatcheries these days. → Follow the product recommendations for optimal efficiency. → Keep in mind the temperature of the air surrounding the eggs during sanitation – this should be at least 20°C. |

Ensuring viability of the embryo

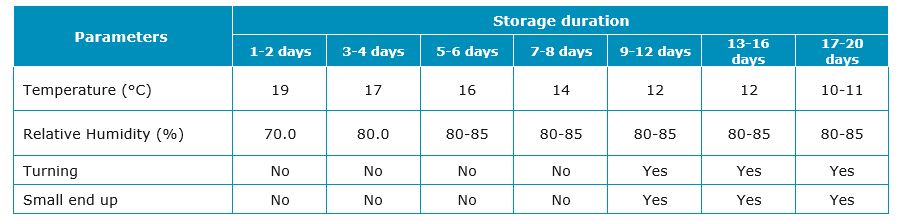

Nowadays, various practices can be applied to secure the viability of the embryo. Storage conditions play an important role in achieving good hatchability and production of chick quality. The longer the storage duration, the colder the storage setting temperature needs to be. Table 2 gives recommendations for temperature and humidity according to storage duration.

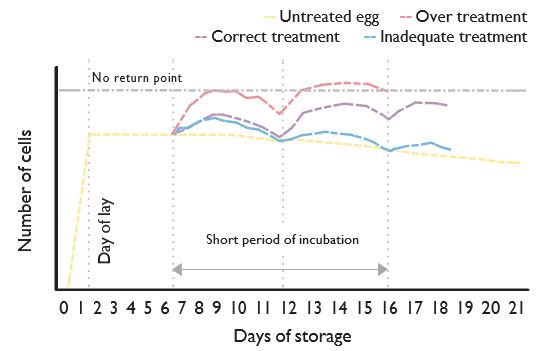

Another common practice to secure embryo viability in the event of extended storage time is SPIDES (Short Period of Incubation During Egg Storage). This technique consists of applying a short period of heat treatment during egg storage. It is the most efficient technique to secure hatchery performance.

At oviposition, the stage of development of the blastoderm is referred to as Grade 10. Unfortunately, this stage is less stable during storage than Grade 12. A common practice is to heat the hatching egg to reach a more stable stage in order to secure the viability of the embryo for a long storage duration.

A total treatment of more than 12 hours must be avoided, meaning three four-hour treatments at five- day intervals at a minimum temperature of 32°C. Some hatcheries apply this treatment only once before five days of storage, others apply it two or three times. Heat treatment not only improves hatchability, but also chick quality.

| RULE OF THUMB TO SECURE THE VIABILITY OF THE EMBRYO | → Handle eggs with care, from collection to farm storage. → From collection to farm storage, leave the hatching egg to cool down steadily. → Ensure environmental uniformity between farm and hatchery storage (temperature and humidity). → Temperature fluctuations must be avoided (impact on early mortality). → Store the hatching egg below 20˚C (18-20˚C). → Transportation conditions need to be at 18-20˚C, but not above. → At the hatchery, follow the storage recommendations for different storage durations. → Turning eggs a minimum of four times a day during storage can be implemented to limit hatchability depletion. → Storing the hatching eggs small end up also limits hatchability loss. → Apply the SPIDES technique to secure the viability of the embryo for long storage. |

Today with new incubation technology, conditions of production are much more secure than before. A good knowledge of embryology is necessary in order to implement these techniques.

CONCLUSION

Production of quality chicks requires proper management at farm level to produce good quality hatching eggs. Preserving the viability of the embryo is the responsibility of the farm and the hatchery. Without proper environmental storage conditions, hatchery performance cannot be optimised. Good knowledge at all levels is essential in order to secure hatchery performance.

Published in International Hatchery Pratice n°35.4 – May 2021